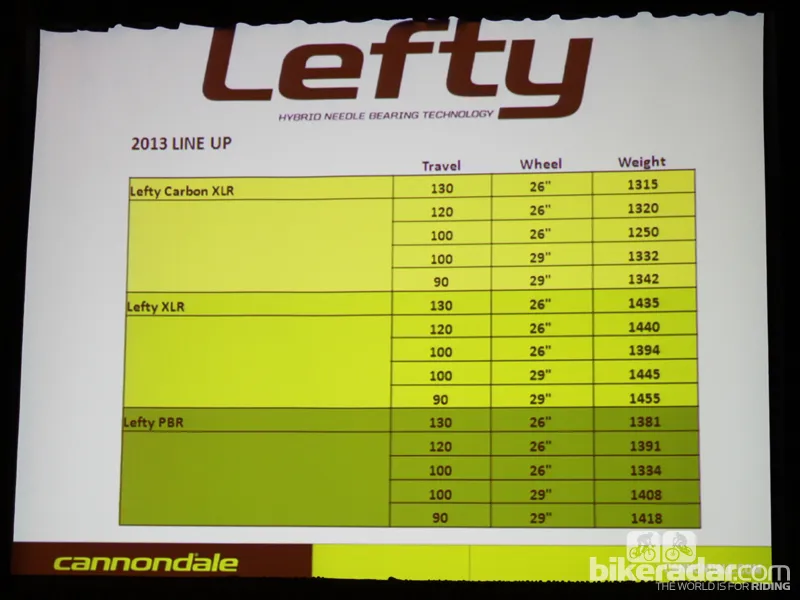

Cannondale’s launch of the Trigger Over Mountain bike also served to introduce the manufacturer’s latest Lefty suspension fork. Cannondale will offer three Lefty models for 2013 – PBR, XLR and Carbon XLR. There’ll be three travel options for 26in wheels – 130mm, 120mm and 100mm – and two for 29ers – 100mm and 90mm.

At the heart of the new fork is the company’s Hybrid Needle Bearing Technology, which pairs Cannondale’s trademark square stanchion and needle bearing designs with a lower, fixed traditional bushing.

“This is the biggest innovation that we’ve made in a long, long time, since its inception,” said Drew Hanna, Cannondale’s Lefty product manager. “For the last 13 years we’ve been the lightest, stiffest, strongest and smoothest fork in the industry,” said Hanna. “We’re lighter than your lightest cross-country forks. We’re stiffer and stronger than your all-mountain forks and we’re smoother than all forks under all types of loads.”

The three forks share two chassis designs and two different dampers. The Lefty PBR uses Cannondale’s OPI 3D forged aluminum upper and lower chassis with the PBR damper, which offers push-button platform adjustment and a rebound adjuster at the top of the fork’s leg.

The Lefty XLR uses the alloy chassis but with a RockShox XLoc bar-mounted remote. Finally, the top-tier Lefty Carbon XLR also features the XLoc but pairs it with a filament-wound upper leg with bonded alloy dual crown clamps, for a 100g weight saving.

The new Lefty chassis

Hanna said that the inverted structure of the forks puts material where it’s most needed, and allows Cannondale engineers to use less material more efficiently: “The key behind all of those characteristics is our dual crown inverted design and the needle bearing system.”

Lefty product manager Drew Hanna with the latest edition of the fork

The lower leg (sliding stanchion) on the new Lefty is just 32mm. But the key to the fork’s stiffness lies at the top of this stanchion, where Cannondale taper the tube from round to square. A four-piece needle bearing system is the fork’s main anchor for stiffness, strength and smoothness.

“The larger top tube allows us to distribute the forces more evenly in the zone where it’s concentrated,” said Hanna. “With Lefty we use a double clamp, and we get a nice stiff structure.

“The other key ingredient, which you don’t see from the outside and is something we’ve had from the beginning – the hallmark of all things Headshok, is the square-in-square design,” said Hanna. “It’s a square peg in a square hole and that just fights all torsional forces to give us that point-and-shoot handling we’ve always had.”

Cannondale still use needle bearings for the main source of the Lefty’s stiffness

A final key feature for the new Lefty is the use of the needle bearings instead of bushings. “We can load those bearings with any force from the riding conditions you see – fore/aft, torsional… No matter what you do the bearings always roll smoothly,” said Hanna.

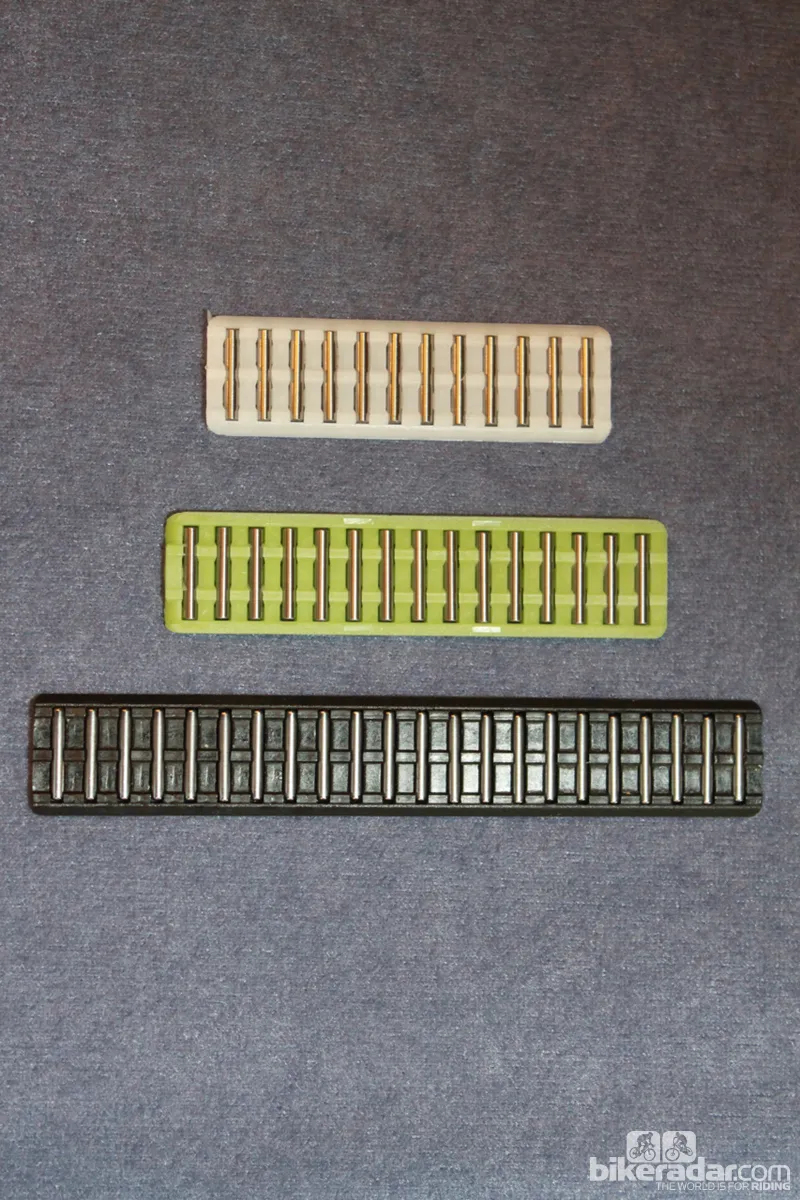

Hybrid Needle Bearing Technology

The new sealed Hybrid Bearing Technology allows Cannondale to get rid of their lower shock boot, which has been a trademark of the Lefty design since its introduction.

Because it’s impossible to seal a square structure, Cannondale have made the new Lefty’s Teflon-impregnated, hard-anodized lower leg round. This means they can incorporate a wiper seal at the bottom of the upper structure. Just above the seal you find what Cannondale are calling a ‘slide bearing’, which is what we commonly refer to as a bushing.

Because the bushing sits in a fixed position on the outer leg and the needle bearings roll into the fork with the inner leg, Cannondale can make a legitimate claim that their fork gets stiffer as the fork gets deeper into its travel. Unlike traditional forks, where the bushing spacing is a constant, in the Lefty the distance between the lower bushing and upper needle bearings increases as the fork moves through its travel. This adds stiffness. Cannondale say it’s this feature that allowed them to bring Lefty to the longer-travel Over Mountain category.

Note the increasing stance between the lower bushing and upper needle bearings as travel progresses

Cannondale also take advantage of the Lefty’s inverted design and new lower seal to incorporate an oil bath, which lubricates both the bushing and needle bearings as the fork moves through its travel.

“Our system takes advantage of the inverted design and fills the cavity [between the inner and outer legs] to create a lubricating oil bath,” said Hanna. “In traditional forks, gravity is taking the oil away from you at all times, and with our system it keeps the oil in place. Essentially, it’s completely encased [submerged] throughout its riding life.”

Setting sag is easier too, as Cannondale now place an O-ring on the lower leg so that sag can be set visually, as with any other fork. Previously, riders needed another person to manually take the measurement.

Isolated damper

“We actually own a patent on cartridge style dampers,” said Hanna. “You’ll see some other guys in the industry using it. We play well with other suspension companies, so we’re not enforcing that patent, but I want you to know we came up with it.”

Cannondale’s isolated damper is like other closed models, in which the main purpose is to keep air and oil separate. This increases resistance to cavitation (the emulsification of the damper’s fluid) and allows for use of less oil overall, to keep the system lighter.

Lefty’s new isolated cartridge damper

The compression damper is called ‘Pop Top’, which Cannondale say offers an efficient platform-style ride with a blow-off to keep the front wheel glued to the ground. Internally, the damper has high- and low-speed circuitry for compression and rebound, which Cannondale also describe as speed sensitive.

“We spend a lot of time on the dynos, and we’re very happy with the design,” said Hanna. “But in an effort to beef them up we’ve introduced an alloy oil cap, with an integrated glide bearing and a polyurethane U-cup seal.”

This replaces the previous plastic design, and Hanna says it makes the damper twice as durable.

Overall, the XLR and PBR dampers essentially work the same. They only differ by way of their Pop Top engagement. The XLR relies on RockShox’s hydraulic remote XLoc, where as PBR uses a mechanical push button at the top of the fork’s leg.

Because the system is a closed unit, it can be completely removed for service. Cannondale also offer a SWOP (Service Without Problems) exchange service where the damper can be removed and replaced at a reduced cost. The brand also offer a lifetime warranty for the inner and outer legs.

The cartridge is sprung by a RockShox’s Solo Air spring, which was co-developed for Lefty and pressurizes both positive and negative air chambers together when setting the positive air pressure.

Cannondale have made the new Lefty’s damper cartridge retrofitable to previous Lefty models dating back to 2005.