Paul Lew, Reynolds’ director of technology and innovation, brings a system approach to the Reynolds carbon wheel line — we profiled the 2013 road line last week — not only in the traditional sense of hubs, spokes, and rims, but also within the construction of the rims themselves. That approach allows Reynolds to build three carbon fiber mountain bike rims that are light and, they say, stronger, stiffer and more durable than their competitors' products.

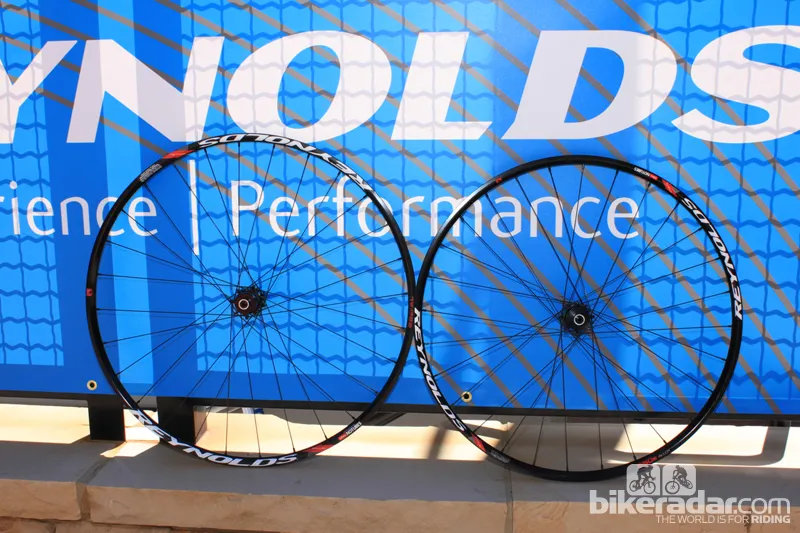

Mountain models: all-mountain, 650b and 29er

Reynolds’ three new 2013 mountain wheels share a rim design philosophy, thought it’s modified in each case to best fit the intended use of the wheels. The All-mountain and 650b models share a similar profile, which measures 26mm tall and 21mm wide (internally), while the 29in model’s profile shares the 21mm inner dimension, but grows vertically to 28mm so to add a bit more stiffness to the larger diameter hoop. All three rims are tubeless ready — in terms of profile — and sealed using NoTubes.com rim tape. “The tubeless hook bead system is proprietary,” said Rob Aguero, Reynolds’ marketing director. “It’s meant to fit a tubeless bead and is very resistant to burping.”

Reynolds’ anti-burp tubeless-ready inner rim profile

All three models share the same 7075 alloy Reynolds’ spec’d hubs, which accept all common quick-release and through axle options — 9mm QR, 15- and 20mm through, front; 10mm QR, 135mm and 142mm through, rear — accept 6-bolt rotors, and straight pull spokes. The hubs are claimed 55g lighter per set than the prior traditionally flanged model.

Reynolds use DT Swiss Revolution spokes throughout; the All-mountain set uses 28 laced cross three, where as the 650b and 29er go lighter with 24 spokes in a cross two lacing pattern.

The wheel packages come together with the following stats (all Reynolds claimed):

- All-mountain: 450g rim, 1,590g wheelset, $1,800

- 650b: 450g rim, 1,590g wheelset, $1,950

- 29er: 435g rim, 1,575g wheelset, $1,950

Each package includes rim tape, valve stems, skewers and hub end caps for axle compatibility. The rims come with a two-year warranty and are eligible for the RAP (Reynolds Assurance Program/ Reynolds Aggressive Protection), which for an additional $250 Reynolds will replace the wheel, no questions asked.

Supporting components for the new carbon wheels: tubeless tape, valve stems, and end-caps

Building the rims: MR5 design

All three of Reynolds’ mountain carbon wheelsets are designed using a similar technology, which focus different carbon material and resins to meet the needs of five critical areas within the rim: spoke face, nipple bed, sidewall, tire channel and the rim hook bead.

Catering to these five areas, Reynolds use five different types of carbon fiber in their mountain wheels (MR5), which lead them to call it a hybrid rim. The goal of the rim design is to align the different performance requirements of the rim with different materials and chemistry. “We do all of our own [resin] chemistry,” said Lew.

Reynolds have branded their custom ‘chemistry’ with the following acronyms: HML stands for Hybrid Modulus Laminate, i.e. multiple types of carbon selected for each specific type of load or job. VRC describes matching the epoxy resin with each specific type of carbon fiber. And finally IGC, or Inert Gas Compaction, describes the use of an inert gas in their bladder molding to insure that there’s chemical transfer during the molding process that might affect the rims integrity.

Lew used the example of the spoke face; here a high modulus carbon that’s impregnated with a high-tension epoxy best supports high point loads from the spokes. But in the hook bead area, a lower modulus carbon that’s more resistant to compression is the best solution. These themes continue throughout and lead to Reynolds’ use of more than 250 pieces of carbon strategically laid into each rim.

A good look at Reynolds’ proprietary bead hooks

And that carbon is custom too. Reynolds’ source all of their carbon from Mitsubishi Japan. The raw carbon is first shipped to a ‘secret’ manufacturing facility in Southern California where Reynolds manufacturer their own pre-preg (by impregnating it with different epoxies depending on end use) and then ship it back to Asia, specifically Taiwan for the actual manufacture of the rims. “The cost savings on labor still make it necessary,” said Aguero.

Aguero also explained that OE partnerships also make their Taiwanese manufacturing sensible, considering that many of the bikes that spec’ the wheels are assembled in Asia. While Cannondale carry out assembly of their bikes in three global centers — Europe, Asia, and the US — Aguero used their 2013 OE use of Reynolds’ carbon wheels on four models as an example for the advantage of Asian manufacturing; Cannondale spec’d upwards of 6,000 carbon wheels for the coming season.

Reynolds Composites meet Paul Lew

While Reynolds started as a steel tubing manufacturer in Birmingham, England in 1889, the composites branch, which made their name with the Ouzo Pro fork was an American licensee of the brand name established in 1999, and that company sold to the MacLean-Fogg automotive company in 2002.

Paul Lew made his first carbon clincher in 1989, and after building wheels under his name for more than a decade, and after Reynolds sale to MacLean, the company bought Lew’s company 2003.

The brand hired Paul Lew back on in 2009 for his current role, which includes running Reynolds Composite Studio. Reynolds describe the ‘Composite Studio’ as a team of talented engineers who work at ‘secret’ location designing wheels, composite blends and develop resins all with the goal of designing the best carbon bicycle wheels.

Lew influences the chemistry and overall design found in all of Reynolds’ carbon wheels, both road and mountain. The mountain rims are designed first and foremost for strength say Reynolds, then for performance, whether that is stiffness, lightweight, or aerodynamics (on the road). “We’re looking for continuous improvement,” said Lew. “And we look to meet or exceed the performance of every previous edition with each new product.”

Aluminum options too: 29er and 650b Alloy

Reynolds round out their 2013 line with two new aluminum alloy mountain wheels: 29er Alloy and 650b Alloy. The alloy models use the same hubs as the carbon wheels, but substituted a heavier gauge spoke and Stan’s NoTubes.com made rim for the wheels. Reynolds select the Crest profile for both, but specify a custom 28-hole drilling for the 650b model.

Reynolds will have two aluminum wheels for 2013 —29in and 650b — built with the same straight-pull hubs used in the carbon wheels